晶圆厂

晶圆厂 -用于在半导体晶片上形成IC结构和分立器件的洁净室和线路

1、10、100、1000类晶体生产的总生产能力为:

板材加工Ø200毫米,设计标准为0.35微米-8.4千件/年

板材加工Ø150毫米,设计标准为0.8微米-78.5千件/年

板材加工Ø100毫米与1.2微米的设计标准-355千件/年

板材加工Ø100毫米,设计标准为2.0微米-18万件/年

板材生产

直径为100,150,200毫米的单晶硅(PMC)的ПWafers

用于生产微电子器件:

-直径为100毫米,用于设计标准超过1.2微米的微电子器件;

-直径为150毫米,用于设计标准为0.8微米的微电子器件;

-直径为200毫米,用于设计标准为0.5-0.35微米的微电子器件。

功率:

微电子器件用单晶硅片(PMS)的生产

-直径为100mm-805千件。 每年;

-直径为150mm-150千件。 每年;

-直径为200mm-10千件。 年。

洁净室:

-1级-195平方 m.

-10-920平方米 m.

-类100-1635sq. m.

-1000-6500平方米 m.

-类10000-4133sq. m.

-类100000-16287平方. m.

晶体生产的技术可能性:

CMOS技术,035μm,2PCC,3Me

BiCMOS技术,0.8μm,3PCC,2Me

高压CMOS技术,0.8μm,2PCC,1Me

双极技术,1.5...5μm,1-2Me

BiKDMOS,DMOS技术,0.8...2μm,1Me

微波双极晶体管技术

肖特基二极管技术

逆扩散分离晶闸管平面制造技术

用于制造硅半导体器件的外延-平面和扩散-平面技术,包括大功率高压晶体管

装配

在创建必要的半导体结构后,将板切割成单个晶体(芯片)。

封装时,晶体(芯片)粘在一个特殊的阀座上,并用导线(焊接)与外壳引线进行电气连接。 然后将本体密封。

封装分立器件的装配线:

-等级:10000件;2440万件/年

芯片封装装配线:

-等级:10000;450万件/月(塑料箱)

每月100万件(金属陶瓷外壳)

-级100000;3450万件/年

装配生产技术:

组装微电路在塑料外壳的类型:SO,DIP,P-SOT223-4-1,P-SOT223-4-2,P-TO-5-11,P-TO-5-12,TO-220AB/5,TO-220AB/7,P-TO-220-7-180,P-至-220-7-230,SIL-3P,SIL-9P,SIL-9MPF,

DBS-9P,DBS-9MPF,SOT523-1,SIL-13P,SIL-15P,QFP-80,QFP-100

半导体组件:

-在塑料案件例如:TO-92,TO-126,TO-218,TO-220,DPACK,D2PACK,IPACK,SOT-23。,

-在玻璃到金属的情况下,如:TO-3,TO-18,TO-72,案件22a-01。

Quality Management System

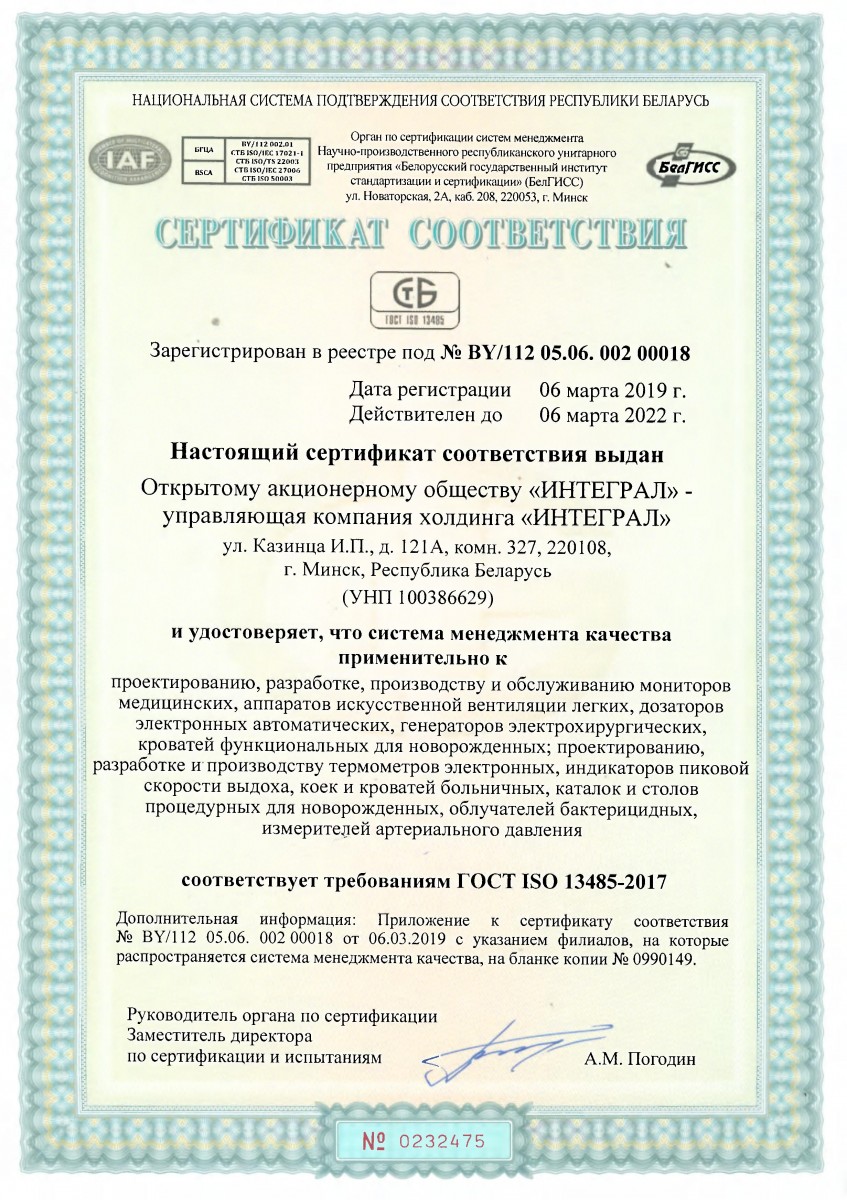

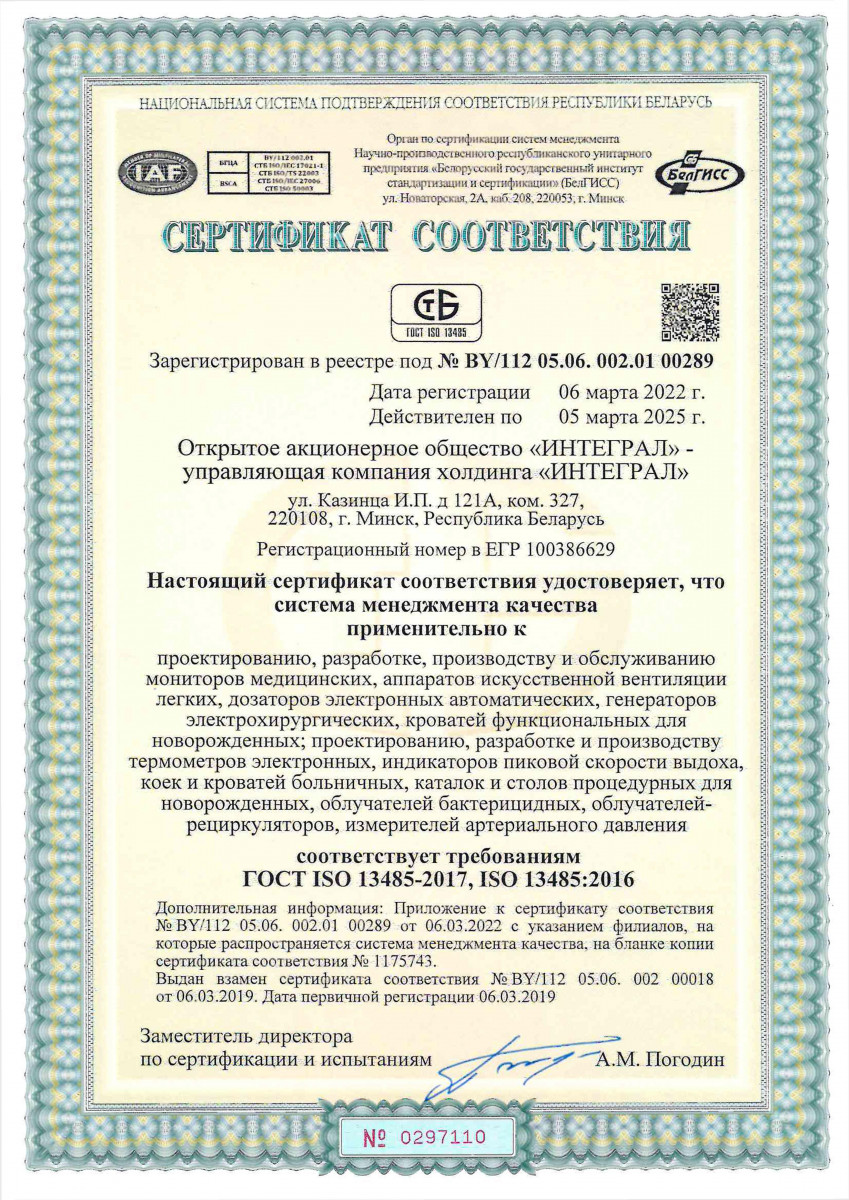

2003年,作为NPO Integral一部分的企业,在kema(荷兰)和Nprup"BelGISS"(白俄罗斯共和国)的认证机构中创建,实施和认证了符合ISO9001:2001(STB ISO9001:2001)要求的质量管理体系(QMS)。

目前质量管理体系的主要任务是结合全体员工的努力,设计、生产和销售最能满足消费者要求和要求的高品质、有竞争力和技术含量的微电子元件、医疗产品和电子产品。

INTEGRAL holding的管理公司OJSC INTEGRAL的QMS正在不断改进和完善,制造产品质量的提高证明了这一点,同时考虑到新需求的形成,以及对可能出现的问题的早期预警。

2021年,在集成电路、半导体器件、液晶指示器、单晶硅板、LED灯、信息系统、电子壁和桌面时钟、电子秒表、电子秒表时钟、收银机、焊接聚乙烯薄膜设备的供应方面,综合ojsc的QMS在2020年重新认证,并确认其符合STB ISO9001-2015标准的要求。白俄罗斯共和国和dineniso9001:2015在德国dakks认证系统.

In 2021 QMS JSC "INTEGRAL" is the managing company of the holding

"INTEGRAL", including the branches "Plant of Semiconductor Devices", "Transistor", Scientific and Technical Center "Belmicrosystems", "Kamerton", is re-certified for compliance with the requirements & nbsp; GOST R ISO 9001-2015 in the Electronsert voluntary certification system and applies to the development and production of electronic component base (integrated circuits and semiconductor devices) for special purposes.

In 2018, OJSC INTEGRAL is the holding's management company

"INTEGRAL", including the branches of the Scientific and Technical Center "Belmicrosystems", "Plant "Electronics" and "Kamerton", created and implemented a quality management system in relation to the design, development, production and maintenance of medical devices, which in 2019 was certified for compliance

GOST ISO 13485-2017 in the National system of conformity assessment of the Republic of Belarus.

The functions of organizing work to ensure the effective functioning of the quality management systems operating in INTEGRAL OJSC - the management company of the INTEGRAL holding, maintaining in working (actual) condition and planning work to improve them are assigned to the quality management service, which also performs the functions technical regulation and standardization, metrological support and quality control of development and manufacturing products at all stages of their life cycle. The service reports directly to the CEO.

For the successful implementation of the tasks assigned to the quality management service, its organizational structure has a compact form and includes five internal structural divisions: the coordinating center, quality management, metrology department, standardization department and the central factory laboratory, reporting directly to the head of the quality management service, who is the representative quality guidelines.

Quality Management Service of JSC "INTEGRAL" - manager the INTEGRAL holding company has subdivisions accredited for compliance with the requirements of GOST ISO / IEC 17025-2019 - a testing center for quality management, a metrology department, a central factory laboratory with areas of accreditation defined by annexes to accreditation certificates.

Quality policy of OJSC "INTEGRAL" - the management company of the holding "INTEGRAL" for 2022

Quality objectives of OJSC "INTEGRAL" - the management company of the holding "INTEGRAL" for 2022

Politics in the field of QMS quality of medical devices

Objectives in the field of QMS quality of medical devices for 2022

Information security policy of OJSC "INTEGRAL" - the management company of the holding "INTEGRAL" for 2021